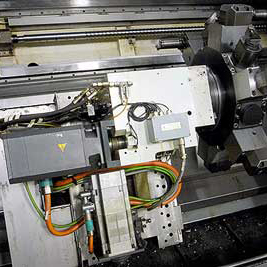

With more than 40 years of experience in mechanical engineering and servicing, All CNC Service and Sales is the ideal maintenance and servicing solution for all generations of machinery, new or old. We specialize in DeckelMahoGildemeister (DMG) / DMG MORI CNC manufacturing products and Siemens and Heidenhain controls. All CNC is also the sole-authorized U.S. sales and service provider for Rotoclear products.

Our service team ensures maximum machine availability and productivity. Our unique, comprehensive service network guarantees that your machining tools are quickly and reliably made operational in the event of a problem. Our highly qualified service technicians are always available to help you via the service hotline, or professional on-site servicing.

Whether it is repairing a failed machine, a comprehensive maintenance servicing or a productivity consultation — All CNC Service & Sales strives to provide a level of service that is second-to-none, offering solutions to maintain maximum productivity during a crisis and minimize machine downtime.

Service is our business

We are dedicated to meeting your service needs with promptness and professionalism.

CNC’s highly experienced service technicians are qualified to quickly diagnose & repair system failures of all kinds, including:

- Communication

- Electrical

- Hydraulic

- Mechanical

- Pneumatic

- Programming

Our service technicians keep your downtime to a minimum and are able to quickly locate any necessary replacement parts.

During scheduled service calls, our technicians will assess potential machine failures, preventing further unexpected downtime.

Preventative Maintenance

Most machine shops overlook routine care of one of their greatest investments ... their machines!

- Machines older than one year need preventative maintenance on a quarterly, bi-annual or annual basis.

- Most costly repairs to machine tools are a result of lack of lubrication and/or undetected minor problems that could have been eliminated with routine preventative maintenance.

- A preventative maintenance program from All CNC offers more than just fluid changes. Your machine will undergo an in-depth inspection process and upon completion, you will be provided with a detailed report.

- Regular preventative maintenance can be performed during non-operational hours, so there is no loss of valuable production time.

Calibrations

Keeping your machine running at the highest level of accuracy.

At All CNC, we can perform the following calibrations:

- Pitch error compensation

- Ball bar diagnostics

- Machine laser measurements and calibration